Foundry and production process

The foundry is the beating heart and original nucleus of our company: here, in 1910, the story of Fonderie Ariotti began.

We are specialised in large size castings, in ferritic nodular cast iron, pearlitic cast iron, grey cast iron and ductile iron for ADI, weighing up to 80 tons. Our plant covers a surface area of over 15,000 square metres and is equipped with cutting edge systems.

We scrupulously comply with all environmental and safety regulations, to ensure the present and the future of the company with a view to sustainability.

Production Process

Our production process integrates all the technologies necessary for production: from the design and construction of the pattern, to the casting, to the heat treatment and deburring of the pieces.

Pattern stock

A 4.0 safe, compactable and automated

Our new and ultra modern pattern stock is automated and compactable on mobile bases, digitally integrated 4.0 and equipped with the most modern technologies:

Pattern shop

Solutions for all applications

Thanks to our mix of abilities, we can design customised patterns to meet all application needs.

Moulding for large castings

For one-off pieces or small serial production

The staff at Fonderie Ariotti can make flasts of up to 8 metres for large iron castings of up to 70 tons.

Moulding for small castings

Castings from 10 to 400 kg

We make castings from 10 to 400 kg for the renewable energy industry, for machine tools, presses and infrastructures.

Casting

The melting department

In 2 electric furnaces – of 16 and 32 ton capacity, and in a 20 ton capacity gas furnace, we melt ferritic nodular cast iron and pearlitic nodular iron, grey cast iron and ductile iron for ADI.

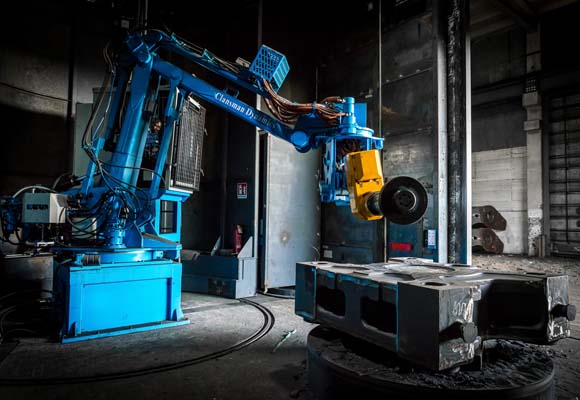

Deburring

A maximum safety department

The in-house deburring department is made up of 6 suction chambers for manual machining, and by a double station Clansmann manipulator.

Painting

A dedicated environment for finishing castings

In a specific industrial shed, with heating and fan extraction, we carry out the painting process using one-component and two-component paints and water-based paints.

Heat treatments

With a bogie heart furnace

Our foundry has a bogie heart furnace for stress relieving, ferritisation and normalising heat treatments.

Tests and measurements

A specialist laboratory

We carry out detailed and accurate tests on all products, thanks to modern instrumentation.

Machining

An outstanding mechanical shop

We have 5-axis CNC machines with a 70 ton capacity; a Carnaghi vertical lathe and a ZEISS measuring machine.