The design implications of the microstructural peculiarities of spheroidal cast iron castings

Because of its high castability, due to its high carbon content, cast iron is often used to make large castings for the energy, machine tool, press and infrastructure industries. To prevent the carbon from falling as brittle carbides during solidification, small amounts of silicon and magnesium are added to the solidification bath to promote the precipitation of carbon as spheroidal graphite nodules. The microstructure of a spheroidal cast iron casting is, therefore, typically made up of a metal matrix (ferritic, pearlitic, austenitic, etc.), in which graphitic nodules (possibly degenerated from the ideal spherical shape) and shrinkage porosity defects are immersed. Danilo Lusuardi, R&D and technical director of Fonderie Ariotti, and Prof. Matteo Benedetti of the University of Trento (UniTN, Department of Industrial Engineering) are working together to develop static and fatigue strength criteria that can capture the microstructural peculiarities that clearly distinguish spheroidal cast iron from a classic forged steel.

The predictive method is the subject of a PhD funded by the CNR and awarded by UniTN.

At the University of Trento, the definition and validation of predictive methods such as the one we explain below, extended to different families of cast iron, are also the subject of a PhD in Industrial Innovation, which started at the end of 2021, and whose call for applications was won by Mr. Matteo Pedranz. The value of the topics covered and of the approach to the subject was also recognized by the CNR, which financed 50% of the doctorate itself, choosing it from among numerous others in various disciplines. The same PhD also won a best poster competition award assigned by the PhD school in Industrial Innovation of the University of Trento.

Steel and cast iron: differences between two classes of metal materials

classes of metallic materials.

| Steel (wrought) | Cast iron | |

|---|---|---|

| Crack initiation site | Inclusions (small, narrow band) | Shrinkage porosity (large, broad band) |

| Critical plane | Maximum shear stress | Maximum normal stress |

| Sensitivity to mean stress | Moderate (tension) Low (torsion) | High |

| Sensitivity to hydostratic stress | Low (static) Moderate (fatigue) | High |

| Notch sensitivity | Moderate-high | Low |

| Roughness sensitivity | Moderate-high | Low |

| Fatigue crack growth threshold | Low | Moderate-high |

| Fracture toughness | Moderate-high | Moderate-low |

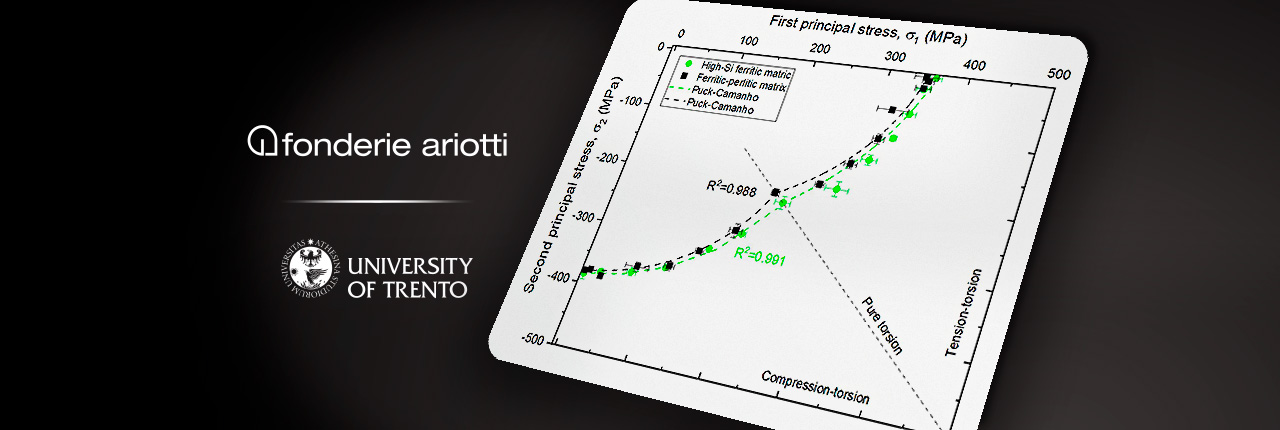

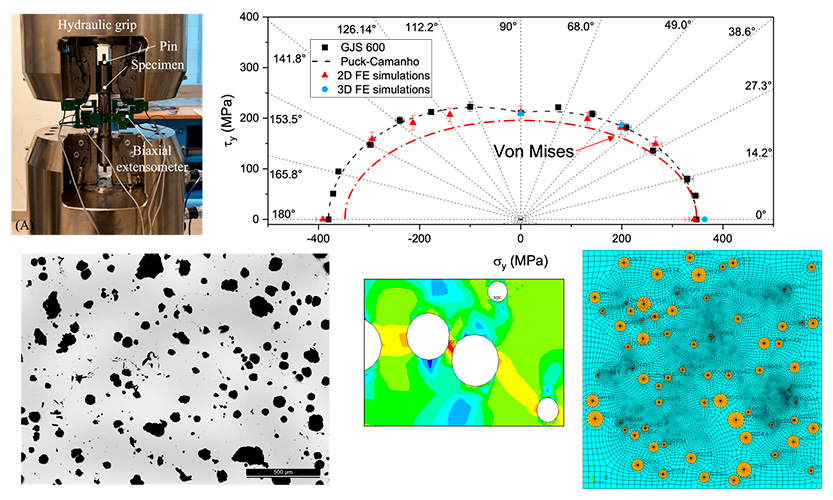

From the table, it is evident that the strength criteria developed for homogeneous materials, such as wrought steels, are unable to capture the microstructural characteristics of nodular cast iron, whose mechanical behaviour needs to be analysed using alternative approaches. Figure 1. shows, in this regard, the results of an extensive experimental campaign based on biaxial static tests (axial action + torsion), conducted at the University of Trento. These tests made it possible to define the yield domain of the material, i.e. the set of points lying on the elastic frontier (any further increase in stress would lead to plastic deformations). It can be seen that this frontier is significantly different from the elliptical frontier predicted by the von Mises criterion, usually employed in the design of forged steels. On the contrary, the experimental data are in better agreement with the Puck-Camanho criterion originally developed for composite materials. This fact is not surprising, given the composite microstructure of cast iron. Finite element simulations incorporating graphitic nodules in a ductile metal matrix gave results consistent with the experimental ones and allowed to interpret the experimentally observed behaviour. In essence, graphitic nodules, when subjected to tensile stress, do not contribute to load transfer and the consequence is a localisation of the stresses at neighbouring nodules and a ‘cusp’ trend of the elastic frontier. On the contrary, in the presence of compressive stresses, the graphitic nodules behave as a pressurised fluid capable of transferring the load, producing the asymmetry of the tensile and compressive elastic domain.

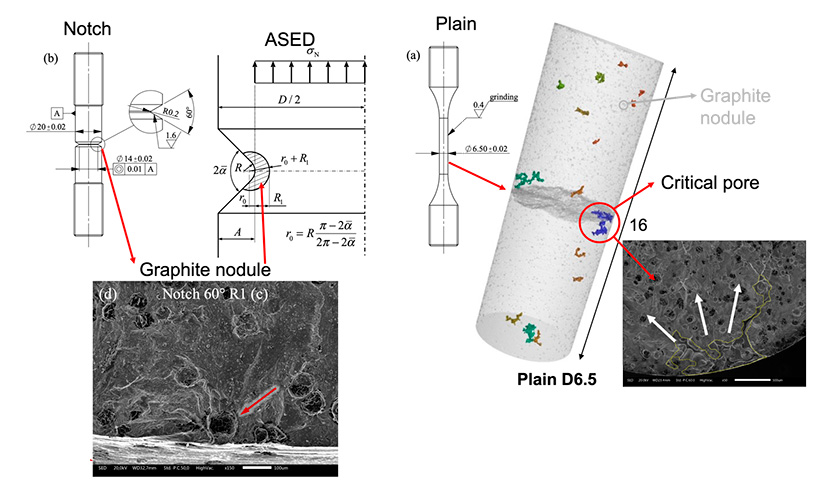

In parallel, multi-axial fatigue tests (axial loading, torsion, combination of the two in-phase and out-of-phase) were conducted with the same servo-hydraulic testing machine on notched and smooth specimens.

The fatigue damage mechanism

Scanning electron microscope analysis and computed tomography scans, on the other hand, made it possible to identify the initiating mechanism of the fatigue damage. This proved to be closely related to the size of the critically stressed volume of material in the fatigued sample. From the study carried out so far on pearlitic cast irons, it appears that the nucleation of the fatigue crack occurs preferentially at a nodule (characteristic dimensions of about 0.15 mm) located near the apex of the notch (small critical volume), and at a large shrinkage pore (characteristic dimensions of about 2 mm) in the case of smooth specimens (large critical volume). We are initiating an equivalent study on ferritic cast irons, in which the different matrix could modify the failure mechanism. This result underlines the need for a probabilistic approach to the fatigue design of a large cast iron casting that allows estimating the probability with which a casting defect will be located within the critically stressed volume of material.

Again, unlike wrought steel, cast iron is a non-homogeneous material whose fatigue strength characteristics depend on the size scale at which the fatigue damage process occurs.

Ariotti Foundries and the University of Trento work together to develop a predictive model

Thanks to the collaboration between Fonderie Ariotti and the University of Trento, a predictive model has been developed that quantifies the effect of the maximum expected defect in the critical volume on the fatigue strength of the casting. In order to take into account the effect of multiaxiality of the stress state and the effect of fatigue notching, Fonderie Ariotti and the University of Trento are reworking a design approach based on the average strain energy density (ASED). This approach has considerable industrial relevance, as it is easily implemented in the post-processing phase of any finite element simulation software and is less mesh-sensitive than prediction methods based on stress and/or strain.